Maintenance by Dr.Pavoni

Daily

After drawing your espresso and milk frothing, flush clean water through the automatic frother and silicone tube by the same method as drawing your milk. If you use the regular steam arm, flush it out with a little steam and wipe away any leftover milk. You may have to turn the high heat switch on again to produce more steam to accomplish these actions. I draw about 3 ounces of water to flush out the silicone tube and the cappuccino auto aerator. This seems to be adequate until the weekly cleaning.

Put a container under the Group. Raise the

arm, and flush the Group out. Some of the grounds tend to get

thrown up toward the insert screen when the water enters the cup

filter when drawing a shot. Flushing out the Group will clean

the insert screen of any residual grounds. Take a wet paper

towel and wipe off the outside face of the inlet screen. Be

careful when doing this, the Group is still very hot.

Lift out the drip tray and rinse it out. Dry

out the cavity below and replace the drip tray. The cavity will rust

in a very short period of time if left neglected! A

replacement base runs about 1/4 of what a new machine costs, so

keep that drip cavity dry.

After the machine has cooled, wipe off

any dried milk, espresso, etc. Empty all water out of the

boiler. Weekly Take off the steam arm or the cappuccino auto

aerator. At this time, take out the small adjustment pin in the

top of the aerator and put it on a paper towel. If you don't, I

guarantee you will lose it, or worse the garage disposal will

eat it. Soak the components in some hot soapy water. This also

applies to the drip tray and silicone tube.

After the components have soaked for a bit,

take a long pipe cleaner

and run it through the silicone tube that

goes to the auto aerator. I go to a craft store and buy the pipe

cleaners. They tend to be longer than the ones you would buy at

a pipe store. If you do your daily maintenance, the tube shouldn't

be that dirty. Flush it with clean water, and place it aside to

dry. Wash and rinse the other components. One piece that is easy

to overlook in cleaning, is the cup filter holder. Coffee oils

build up inside. Use a Brillo®/SOS® pad to clean

the inside of the holder or you could use some Mr. Coffee

solution. Don't use a Brillo®/SOS® pad to clean any chrome

surfaces on the machine!

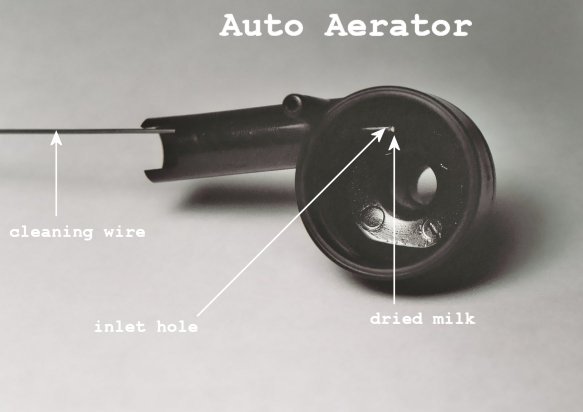

Take apart the cappuccino auto aerator, and

clean the inside. After a while, the inside tends to get a milky

buildup called milkstone. I've tried many things to get this

off, but it seems to get into the plastic, and doesn't want to

come out. I just use a Brillo®/SOS® pad or cleaning pad to get

it as clean as possible. Soaking the auto aerator in a bowl with

some of the Mr. Coffee descaling liquid will get a lot of it

out. There is a milkstone remover product that you can buy but I

don't recommend it. It's Phosphoric Acid which isn't that safe

to use plus you have to buy a gallon of it, which would last you

a lifetime. The inlet hole

in the cappuccino auto aerator where the milk

enters the chamber will eventually start to accumulate dried

milk. Even if you do your daily maintenance, the milk stills

tends to dry up in there. Take a small rigid wire, and clean out

the hole. I use a cake tester.

Use a small diameter wire that is smaller than

the hole. You don't want to enlarge the hole in the aerator. The

milk gets almost like glue, so it may take a little longer then

you would like to clean it. Pipe cleaners don't do any good on

this one! If you don't clean out this hole, it will eventually

affect the way the milk is drawn or not drawn. You'll know when

the only thing that comes out is STEAM!

Wet a paper towel and spread it out under the

Group. Use some Q-tips® and run them around the insert screen

and O-ring gasket. You'll be amazed at the quantity of coffee

grinds that accumulate up there. Wetting the Q-tip® helps. After

the majority of grinds are out, wet another paper towel. Double

or triple fold a corner, and jam it in the groove, and run it

around to get the remainder of the grinds.

Take a soapy paper towel or sponge and wipe

down the chrome surfaces of the machine. Don't use any abrasives

when cleaning the chrome. Dry it off with paper towels or a soft

cloth. Monthly Descale your machine. This is

an important procedure. It will prevent premature replacement of

the fuse in the machines that don't have a resettable fuse.

Monthly descaling may not be necessary if your area has soft

water. Once or twice a year may be sufficient. There are

different descalers that you can use to remove the mineral

buildup on the heating coils. The Pavoni manual recommends the "Urnex"

brand of descaler. I found that one hard to obtain locally. You

can purchase it on the Internet. I use the "Mr. Coffee" brand.

You could use white vinegar to dissolve the deposits. The ratio

of white vinegar to water would be about 50/50. The ratio is not

that important. If you have never descaled your machine you

could use almost straight white vinegar. If you use straight

vinegar, I would just cover the heating coils and add a little

boiling water, just to help loosen the scale. I wouldn't turn

the machine on if you are using straight vinegar. The important

thing to remember is, no matter what you use to descale the

machine, always flush the system out with fresh water after

descaling. Using distilled water for making your espresso is

also another way to go to almost eliminate descaling.

Note: There are two ways I

descale my machine. It depends on the circumstances on which one

I choose. If the fuse blows while the machine is on, mineral

deposits on the heating coil could have accumulated enough and

caused an overheating condition. Shame on me for not doing the

monthly maintenance! With the power off pour boiling

water and the descaling agent in the boiler to the top and let

sit for about an hour. I wouldn't take the chance of replacing

the fuse and descaling it with the power on. The deposits may

still not be dissolved enough and will probably blow the new

fuse. Meanwhile your guests are waiting for their cappuccino!

The other method is the

monthly maintenance. I mix the descaling agent as directed on

the package and pour it in the boiler. I fill the boiler about

an inch from the top. I do this so when you get to operating

pressure, the overflow tube also gets flushed . Cap the boiler

and turn it on just like you would as if you were preparing

espresso. Once you are producing steam, I place a container

under the Group and raise the handle to flush out the Group. I

don't put the cup filter holder on for descaling. Personally, I

really don't think you have to flush out the Group. It is

relatively self-cleaning because of the piston gaskets. They fit

so tight against the piston walls, it would be hard for deposits

to accumulate, but it doesn't hurt to do it. Flush with clean

water after the machine cools down. Note: There is another reason why descaling

your machine could be important. A visitor to the site picked up

on a apparent condition on one of my photographs of inside my

boiler. There was a bluish/green color

at the top of the boiler. This could be a

copper salt/copper acetate residue due to the copper boiler and

dissimilar metals inside the boiler. It could be toxic and I

state could be! No water analysis has been done on the condition.

The good and bad of it is that copper salt is water soluble so

water helps to dissolve it. If you look carefully at the

photograph you won't see any on the rest of the boiler. The bad

thing is your shot of espresso may have a minute amount

of it. I don't want anyone throwing out their Pavonis or selling

them! I'm keeping mine and will continue to make espresso. These

machines have been around for 40+ years and other espresso

machines also have copper boilers too. I think by now if there

was a serious problem it would have risen by now. So the main

thing is to descale your machine regularly and fill the boiler

to the top with the descaling agent. With this method I wouldn't

turn the machine on, just use boiling water and the descaling

agent. You could use a 3M® scouring pad to clean the top

inside part of the boiler where generally there is no water

contact with the boiler surface. I would not recommend using

steel wool. Don't use the scouring pad on the chrome surface of

the machine. You should completely empty your boiler after the

water has cooled so each time you use your machine you're

filling with fresh water. Don't reuse the previous boiler water.

I don't want to unduly scare anyone. Nothing has been definitely

proved on this but it is always best to be safe than sorry. It's

always best to use filtered water for your Pavoni too. It may be

healthier and your espresso may taste better.

Yearly

-

Replace all seals/gaskets if needed. Even if you don't use your machine on a regular basis, the seals or o-rings still could get hard and leak.

-

If you don't replace the piston gaskets, you should still take out the piston assembly and clean it up. The face of the piston will have a buildup of sludge from the coffee grounds. This may have an effect on the quality of your espresso. The inside of the insert screen would also need a good cleaning.

© 2010 Francesco Ceccarelli. All rights reserved.

Reproduction in any form without permission is prohibited.

.jpg)